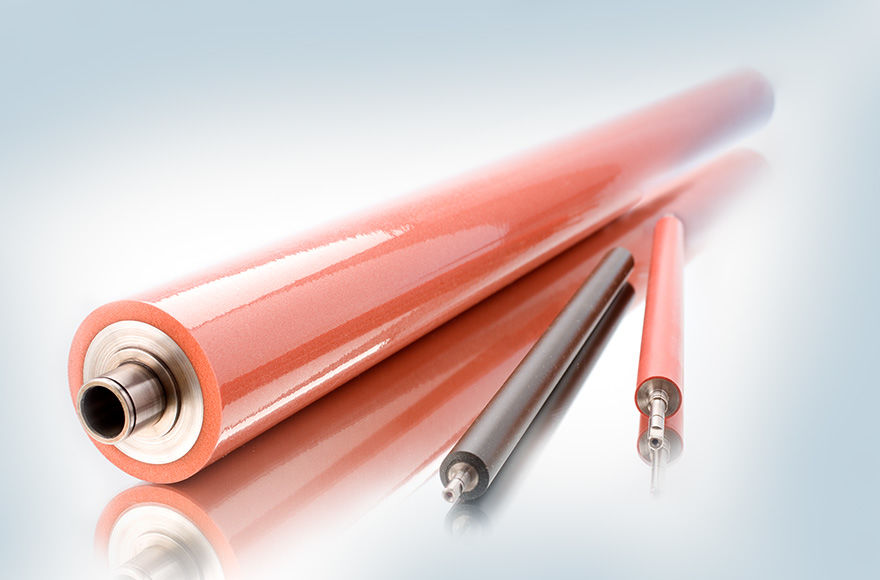

Fuser/Pressure Rollers and Belts

Requirements for products working in a high temperature fusing environment include continuously increasing requests for longer part life, higher print speed, and better print resolution involving ongoing material and process innovations. Our goal is to find the best combination of the following properties:

- Thermal resistance

- Thermal conductivity

- Abrasion resistance

- Anti-adhesive surfaces

- Elastomer hardness

Substitution of Metal Substrates by Polyimide Belts

Fusing by heat and pressure in digital printers has previously been realized with anti-adhesive coatings on aluminum or steel cores. These metal substrates have been increasingly replaced by seamless thin-walled polyimide belts due to energy-saving environmental regulations and the growing requirement for “instant on” printing devices.

Deutsch

Deutsch